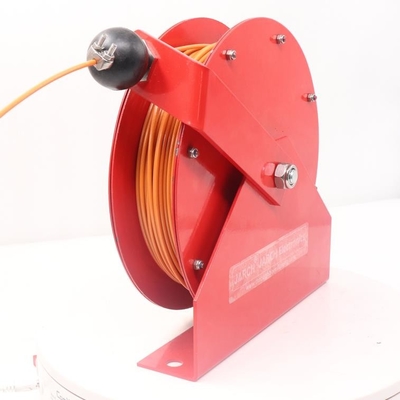

Retractable static grounding earthing enclosed cable reel for tank trucks 15m 30m

Product Details:

| Place of Origin: | Guangdong, China |

| Brand Name: | JARCH |

| Certification: | CE,FCC,ROHS |

| Model Number: | JSR-GA3100 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 2PCS |

|---|---|

| Price: | US$120-300/PER PIECE |

| Packaging Details: | Standard Export Paper carton or custom packing |

| Delivery Time: | 7 working days |

| Payment Terms: | D/P, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability: | 1000 Piece/Pieces per Week |

|

Detail Information |

|||

| Material: | Steel, Red Grounding Reels | Hose Included: | Yes |

|---|---|---|---|

| Weight: | 10KG | Cable Length: | 15M |

| Clamp Rating (AMP): | 100 | REEL Name: | Retractable Static Grounding Earthing Enclosed Cable Reel For Tank Trucks 15m 30m |

Product Description

JARCH Retractable static grounding earthing enclosed cable reel for tank trucks 15m 30m

| JARCH's static discharge reels are used to ground equipment operating in hazardous atmospheres. When properly clamped to the ground, the static discharge reel dissipates static electrical buildup, reducing the chances of sparking and the potential for explosion. *Nylon covered cable (1/8" O.D.). |

![]()

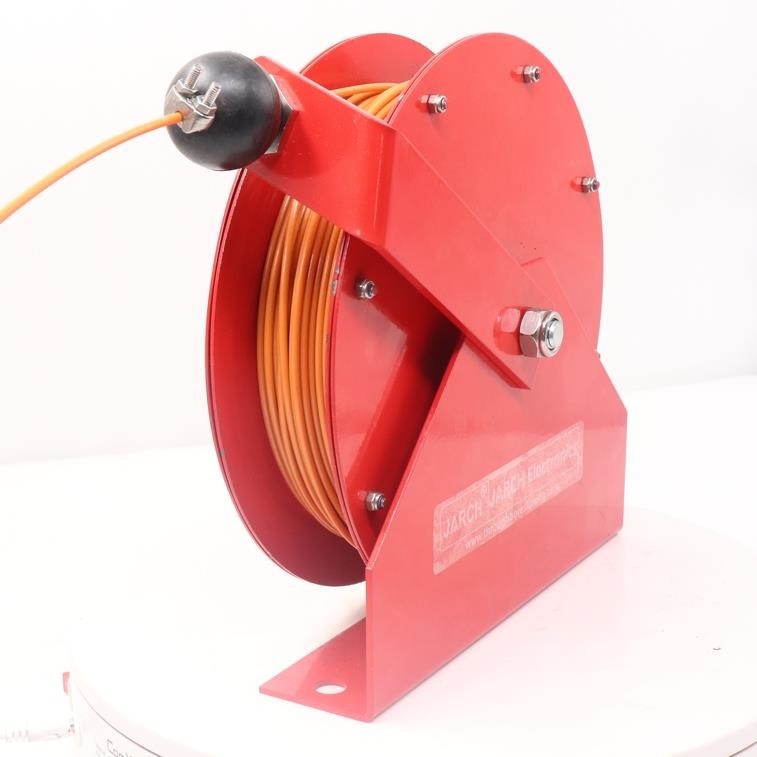

Reel Specifications and Dimensions

![]()

Benefits

***Strength - Made from industrial grade carbon steel.

***Compact design - Reels require little mounting space for applications where space is a critical requirement.

***Corrosion resistance - Steel components are powder coated for superior corrosion resistance. Steel cable available with nylon coating for longer service life.

***Easily adjust spring tension - Loosening two screws allows user to add or remove spring tension.

![]()

JARCH main products:

1. Fiber optic rotary joint series

2. Through bore slip ring series

3. Electro optical slip ring series

4. Hybrid slip ring series

5. Pneumatic rotary joint series

6. Hydraulic rotary union series

7. Capsule slip ring series

8. Pancake slip ring series

9. High current slip ring seriels

10.High speed slip ring series

11.Thermocouple slip ring series

12.Retractable Hose Reel

13.Wind turbine slip ring series

14.Ethernet slip ring series

15.Explosion proof slip ring series

16.Mercury slip ring series

17. Slip Ring Carbon Brush

18.Collector Ring Assembly

![]()

Why to choose JARCH slip ring?

JARCH Company is a professional slip ring manufacturer in Shenzhen, China. JARCH has become one of the best-known Chinese brands in the world for high quality slip rings and first-rate services. Since we were founded in 1998, we have been committed to innovating, developing and manufacturing high quality slip rings and providing perfect rotation solutions for customers around the world.

With more than 19 years' experience in the field, JARCH has established long term business relationships with transnational corporations, research institutes, military-industry departments, famous universities as well as a lot of companies in various industries at home and abroad.

We specialize in custom slip rings solutions tailored to meet your project's requirements for performance, testing, qualification and delivery. Our teams understand the importance of comprehensive project planning ensuring your project's success.

Can't find the right slip rings solution?

At JARCH Company, we strive to meet the needs of our customers. If an assembly from our standard model does not fit your requirements, our design team will work with you to design a slip ring assembly that will meet your company's exact needs. With over 19 years of experience JARCH has amassed over 10,000 drawings, thousands of custom slip ring designs and experiences supporting customers worldwide.

FAQ

A:

If you want to costomize the special slip ring model, you need provide details as below:

a. Operatring speed(RPM)

b. The type of installation

c. Outline size

d. Channels(the No. of single wire besides cable)

e. Rated voltage & current for power rings and signal rings

f. The signal type and related parameters(very important)

g. Operating temperature h.IP(sealing requirements)

2.How long is your production lead time?

A: It needs 7 to 15 days for standard products, 10 to 20 days for simple customized products,

15 to 40 days for complex customized porducts.

To increase spring tension:

Adding wraps of hose will increase spring tension. This can be accomplished by pulling out approximately 10 feet of hose, hand feed hose back up through roller bracket assembly* until loop is large enough to slip over sheave. Add two or three wraps until desired tension is achieved. Do not exceed spring capacity.

To reduce spring tension:

This can be accomplished by removing wraps of hose from the reel sheave. Remove wraps of hose from the sheave, one wrap at a time, until desired tension is obtained.

![]()