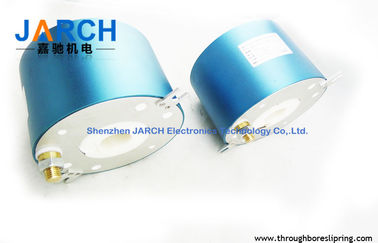

400A High Current Slip Ring

Product Details:

| Place of Origin: | Shenzhen , China |

| Brand Name: | JARCH |

| Certification: | CE,FCC,ROHS |

| Model Number: | JSR-BC035-1P400 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pc |

|---|---|

| Price: | US $ 10 - 30 / Piece |

| Packaging Details: | Gift box or custom packing |

| Delivery Time: | 5-10 days |

| Payment Terms: | Ex-works, L/C,T/T, Western Union, MoneyGram |

| Supply Ability: | 500pcs/week |

|

Detail Information |

|||

| Inner Size: | 35mm | Outer Size: | 168mm |

|---|---|---|---|

| Current: | 400A | Voltage: | 600Vac/Vdc |

| Max Speed: | 50RPM | Protection: | IP54 |

| Circuits: | 1 | Housing Material: | Ss304 |

| Contact Material: | Carbon | ||

| Highlight: | slip ring units,rotary slip rings |

||

Product Description

400A High Current Slip Ring units for wrapping machinery , Rotary Connector

Feature:

High current up to 400A

Max voltage:600Vac/Vdc

ID/OD:35/168mm

Anti-jamming ,very low cost

Very low electric noise

Quick Details:

| Model Number: | JSR-BC035-1P400 | Inner Size(mm): | 35mm |

| Outer Size: | 168mm | Circuits: | 1 |

| Volt AC/DC(V): | mV~600Vac/Vdc | Current(A): | 400A |

| Speed(rpm): | 50 | Protection: | IP54 |

Packaging & Delivery:

| Packaging Details: | Standard Export carton Package |

| Delivery Details: |

Delivery time:15 days after got the payment Shipping:BY DHL, FedEx, UPS or TNT...... |

Description:

Slip rings can be used in any electromechanical system that requires unrestrained, continuous rotation while transferring power or data from a stationary to a rotating structure.

It is also called a rotary electrical interface, Slip Ring Assemblies, Rotary Connector, Slip Ring Units. It can improve electromechanical capability, simplify system design, eliminate possible damage while rotation. It’s the key

The BC035 provides a 35mm through-bore for routing hydraulic or pneumatic lines. The 100~400amps /circuit are available in 1-4 ring.

Benefits:

- Unique signal handling performance with minimal electrical circuit noise

- Very low electric noise

- Anti-jamming ,very low cost

- Very low contact resistance (Less than 1mΩ)

- No maintenance and better reliability than traditional sling rings

- Suitable for signal and power transfer of rotating devices or instruments

Dimensions:

![]()

Specifications

| Rings | 2~36 | Current | 400A |

| Voltage | mV~600VDC/VAC | Max speed | 50RPM |

| Through bore size | 35mm | Overall diameter | 168mm |

| Housing Material | ss304 | Torque | 0.05N.m;+0.03N.m/6rings |

| Working life | 50million | Contact material | carbon |

| Electrical noise | <5 mΩ | Contact Resistance | <2mΩ |

| Dielectric strength | 1000VDC@50Hz | Lead Wire | UL Teflon® Awg26,Awg22 |

| Insulation resistance | 500MΩ@600VDC | Lead Lengths | 300mm(12") |

| Operating Temp. | -40°C to 80°C | Protection | IP54 |

| Materials | Lead Free, ROHS | Certified | CE,FCC |

Applications:

• Packaging / wrapping machinery

• Industrial machinery

• rotary index tables

• Heavy equipment turrets or cable reels

• Emergency lighting, robotics Palletizing machines, Option

• Medical equipment | rotary sensors, emergency lighting, robotics

• Miniature cable reels

Installation Instructions

Shaft Mounted

![]()

Flange mounted:

Jarch main products:

1. Fiber optic rotary joint series

2. Through bore slip ring series

3. Electro optical slip ring series

5. Pneumatic rotary joint series

6. Hydraulic rotary union series

9. High current slip ring seriels

10.High speed slip ring series

11.Thermocouple slip ring series

13.Wind turbine slip ring series

15.Explosion proof slip ring series

Why to choose JARCH slip ring?

JARCH Company is a professional slip ring manufacturer in Shenzhen, China. JARCH has become one of the best-known Chinese brands in the world for high quality slip rings and first-rate services. Since we were founded in 1998, we have been committed to innovating, developing and manufacturing high quality slip rings and providing perfect rotation solutions for customers around the world.

With more than 19 years' experience in the field, JARCH has established long term business relationships with transnational corporations, research institutes, military-industry departments, famous universities as well as a lot of companies in various industries at home and abroad.

We specialize in custom slip rings solutions tailored to meet your project's requirements for performance, testing, qualification and delivery. Our teams understand the importance of comprehensive project planning ensuring your project's success.

Can't find the right slip rings solution?

At JARCH Company, we strive to meet the needs of our customers. If an assembly from our standard model does not fit your requirements, our design team will work with you to design a slip ring assembly that will meet your company's exact needs. With over 19 years of experience JARCH has amassed over 10,000 drawings, thousands of custom slip ring designs and experiences supporting customers worldwide.

FAQ

| Q1: Are you a factory or a trading company? | ||||||||||

| A: We are a professional manufactory with High-level R & D team. | ||||||||||

| Q2: How many types of the slip rings do you have? | ||||||||||

| A: We can supply all kinds of the slip rings.Such as minitary slip ring,customized sliring, miniature slip ring,fiber optical slip ring,RF rotary joint,HD combined-type, disc slip ring,wind power slip ring,solar power slip ring,through-bore slip ring, etc. |

||||||||||

| Q3: Can you supply the slip rings with high frequency signals and(or) optical communication signals. | ||||||||||

| A: Yes, we can supply mixed signals slip rings as your request. | ||||||||||

| Q4: what's the working life of your slip rings. | ||||||||||

| A: 30~50 millions revolutions for standard ones, 50~80 millions revolutions for special ones, We also can supply much higher revolutions as your special requirement. |

||||||||||

| Q5: Do you supply OEM and ODM ? | ||||||||||

| A: Yes, we supply OEM and ODM. | ||||||||||

| Q6: What technical data should be provided for our customized slip ring model. | ||||||||||

|

A: If you want to costomize the special slip ring model, you need provide details as below: a.operatring speed(RPM) c.outline size d.channels(the No. of single wire besides cable) f.the signal type and related g.operating temperature h.IP(sealing requirements) |

||||||||||

| Q7: How long is your production lead time? | ||||||||||

| A: It needs 7 to 15 days for standard products, 10 to 20 days for simple customized products, 15 to 40 days for complex customized porducts. |

||||||||||

| Q8: What's your delivery port? | ||||||||||

| A: Our delivery port is Shenzhen | ||||||||||

| Q9: How do you delivery our goods? | ||||||||||

| A: Usually small orders can be deliveried by air, big orders can be deliveried by sea. It can be negotiated before delivering. |

||||||||||

| Remark: | ||||||||||

| If you have any other question, pls contac us without any hesitation. |